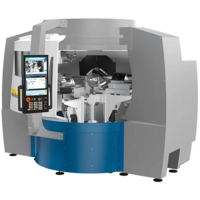

The IMO-FLEX offers maximum flexibility combined with high productivity for small and medium batch sizes. With up to 3 machining stations and a 10-position tool changer above the unit and an optional 50-position chain changer, the IMO-FLEX offers space for up to 80 tools.

The IMO-FLEX is designed to be extremely space-saving and the interfaces are designed to allow flexible linking of several machines. This means that additional units or infeeds and outfeeds can be used multiple times. Efficient and ecological production can be realised in this way!

Click here to go to manufacturer's page: Imoberdorf - IMO FLEX

We are very happy to announce that we are the new official partner of Hardinge Kellenberger AG including the brands Hauser, Tschudin & Voumard on the Czech and Slovakian market.

We had already the chance to represent the grinding brands during the last exhibition in Brno.

TL TECHNOLOGY AG is looking forward to an exciting future.

Click here to go to manufacturer's page: Hardinge Kellenberger

Mu-Tools machine Mµ-HS1 single spindle and Mµ-HS2 double spindle are high precision honing machines suitable for small and large series.

Here's what the machine brings with it:

Honing range from 0.6 mm to 80 mm diameter. QR code transmission of detailed honing information directly into the program. Analysis of the data of each tool to restore the state of wear. Expansion system integrated in the spindle. Recovery of torque, heat and current data for analysis of forces between tool and material. Honing movement performed by a table coupled to a linear motor. Possibility of setting several honing strokes at different positions in the same program. Mechanical or pneumatic workpiece clamping systems. Simple and intuitive parameterisation. Safe settings. Synchronicity between all axes and high repeatability. Camera option to record the setting of the position(s) and the position of the lubrication pipes.

Click here to go to manufacturer's page: Neue MU-HS1

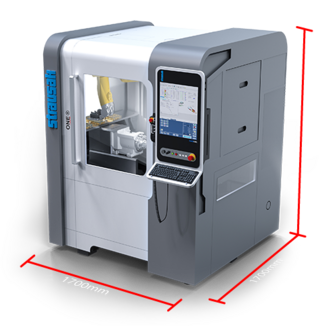

The new STRAUSAK ONE is the ultimate 5-axis CNC-tool grinder for high quality production or resharpening of cutting tools. The high versatility provided by the large selection of equipment allows for the efficient grinding of a large variety of tools up to a diameter of 32.0mm. Furthermore, modern workshops need flexibility, efficient floor space use, lean processes, short setups, and small machines. All this you can find in the NEW Strausak ONE.

Click here to go to the manufacturer's page: New Strausak ONE

The GrindSmart®660XW has been designed for rotary cutting tool applications ranging from diameter 0.1 to 12.7mm in an amazingly compact layout which includes a large capacity tool loader and a high-speed wheel changer with 6 wheel-pack positions. The machine features the latest linear and torque motor technology on each axis, as well as a 14kW synchronous spindle motor. All these components are cooled with the same coolant oil providing a perfect thermal stability, unbeatable accuracy in production as well as extremely good surface finish on the tools.

The machine features 4 linear and 2 rotary axes. The unique aspect is the workhead which is mounted on a CNC linear axis. With this feature, the tool grinding and the well-known Rollomatic peel grinding process are combined together into a single machine model. The benefit of the traveling workhead for peel grinding operations is that the grinding wheel is always on top of the steady rest while the workhead axis is pushing the tool through the grinding wheel, providing excellent process stability. This CNC workhead axis is also a great benefit for drill applications, as an innovative steady rest design combines optimal tool support for fluting and for pointing.

Click here to go to the manufacturer's page : Grindsmart 660XW

Proud successor to the famous Schaublin 110 and its minimal footprint of 2.4 sq m, the new 632 is the result of Schaublin’s unique expertise in the field of high precision lathes.

Versatile and modular, the Schaublin 632 enables the production of both simple and highly complex parts.

The Schaublin 632 is the ideal production tool for the most demanding industries.